Bridge Plugs

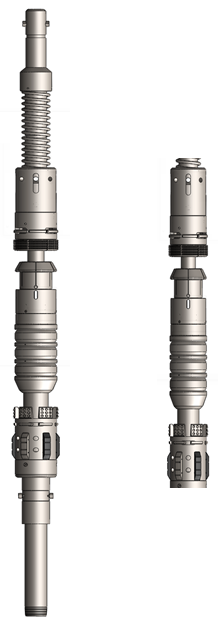

SAZ Oilfield Services offers a wide range of Bridge Plugs for permanent or temporary well bore isolation. Our HydraTMline of Bridge Plugs are based on field proven design and have an extensive track record globally over a wide range of downhole conditions.

Hydra MS Mechanical Set Bridge Plugs are deployed on Tubing or Drill Pipe and set by Snap Latch Setting Tool in either tension or compression. It’s locked construction design and large clearance enables faster and safer run-in speed. Provides optimum strength, easy drillability, and high pressure ratings. Easily converts from Mechanical Set to Wireline set by changing the upper slips. Conversion kit also available to convert from Bridge Plug to Cement Retainer.

Hydra WS Wireline Set Bridge Plugs are deployed on Wireline and set via appropriate Wireline Pressure Setting Assembly and Wireline Adapter Kit. This deployment offers customer a safe and efficient method of placing a drillable Bridge Plug at any predetermined point in the casing without having to dump cement on top to prevent leakage.

Application

- Multi-Zone isolation

- Multi-Zone stimulation

- Plug and Abandonment

Types

- HydraMSTM Mechanical Set

- HydraWSTM Wireline Set

- HydraHMTM Hydraulically Actuated Mechanically Set

- HydraWRTM Wireline/Hydraulic Set Retrievable

Features and Benefits

- Available from 4-1/2’” to 13-3/8” Casing Sizes

- Up to 10,000 psi & 400°F Rating

- Anti-preset mechanism

- Easy conversion to Cement Retainers

- Convertible from Mechanical to Wireline Set and vice versa

- Cast Iron construction, easily drillable

| Hydra WSM Bridge Plug | |||||

|---|---|---|---|---|---|

| Casing | Plug | Setting Range (In) |

Differential Pressure (psi) |

Elastomer | |

| OD (In) |

Weight (PPF) |

OD (In) |

|||

| 4 1/2 | 9.5 - 16.6 | 3.5 | 3.826-4.09 | 8000 | NITRILE / HNBR / AFLAS / VITON |

| 4 1/2 | 9.5 - 13.5 | 3.71 | 3.92-4.56 | ||

| 5 | 11.5 - 21 | 3.71 | 3.92-4.56 | ||

| 5 1/2 | 13 - 25 | 4.24 | 4.58-5.047 | ||

| 5 3/4 | 22.5 - 25.2 | 4.24 | 4.58-5.047 | ||

| 6 5/8 | 17 - 22 | 5.61 | 5.989-6.655 | ||

| 7 | 17 - 35 | 5.61 | 5.989-6.655 | ||

Hydra WSM Wireline Set Bridge Plugs are available from 4-1/2” to 7” casing sizes. These Bridge Plugs are constructed with single piece elastomeric packing elements thereby providing an economical means for zone isolation, fracturing and other wellbore treatments. This plug sustains moderate pressures and temperatures.

Hydra WSB Wireline Set Bridge Plugs are available from 2-3/8” to 20” sizes. These high performance Bridge Plugs contains three piece Elastomeric Elements with metallic back-up rings on either side of the Elements to avoid rubber extrusion in high pressure and high temperature environment. For larger plugs deployed in 9-5/8”, 10-3/4” and 13-3/8” casing sizes, the three piece packing elements are replaced with a single piece element, with option to retain the three piece element design.

| Hydra WSB Bridge Plug | |||||

|---|---|---|---|---|---|

| Casing | Plug | Setting Range (In) |

Differential Pressure (psi) |

Elastomer | |

| OD (In) |

Weight (PPF) |

OD (In) |

|||

| 2 3/8 | 3.3 - 5.9 | 1.71 | 1.867-2.107 | 10000 | NITRILE / HNBR / AFLAS / VITON |

| 2 7/8 | 6.4 - 6.5 | 2.1 | 2.28-2.563 | ||

| 3 1/2 | 5.7 - 10.2 | 2.75 2 | 2.867-3.258 | ||

| 3 1/2 | 12.7 | 2.5 | 2.625-2.75 | ||

| 4 | 5.6 - 14 | 3.12 | 3.34-3.732 | ||

| 4 1/2 | 9.5 - 16.6 | 3.5 | 3.826-4.09 | ||

| 4 1/2 | 9.5 - 13.5 | 3.71 | 3.92-4.56 | ||

| 5 | 11.5 - 21.5 | 3.71 | 3.92-4.56 | ||

| 5 1/2 | 13 - 25 | 4.24 | 4.58-5.047 | ||

| 5 3/4 | 22.5 - 25.2 | 4.24 | 4.58-5.047 | ||

| 6 | 14 - 26 | 4.75 | 5.14-5.595 | ||

| 6 5/8 | 34 | 4.75 | 5.14-5.595 | ||

| 6 | 10.5 - 12 | 5.34 | 5.595-6.366 | ||

| 6 5/8 | 17 - 34 | 5.34 | 5.595-6.366 | ||

| 7 | 23 - 40 | 5.34 | 5.595-6.366 | ||

| 6 5/8 | 17 - 22 | 5.61 | 5.989-6.655 | ||

| 7 | 17 - 35 | 5.61 | 5.989-6.655 | ||

| 7 5/8 | 20 - 39 | 6.09 | 6.625-7.263 | ||

| 8 5/8 | 24 - 49 | 6.96 | 7.511-8.248 | 8000 | |

| 9 5/8 | 29.3 - 53.5 | 7.71 | 8.435-9.063 | ||

| 10 3/4 | 54 - 81 | 8.71 | 9.25-9.784 | 5000 | |

| 10 3/4 | 32.7 - 51 | 9.5 | 9.85-11.15 | ||

| 11 3/4 | 38 - 60 | 9.5 | 9.85-11.15 | ||

| 13 3/8 | 77 - 102 | 11.56 | 11.633-12.464 | 3000 | |

| 13 3/8 | 48 - 72 | 12 | 12.347-12.715 | ||

| 16 | 65 - 109 | 14.25 | 14.688-15.25 | 2000 | |

| 18 5/8 | 76 - 96.5 | 17.25 | 17.655-18.73 | ||

| 20 | 133 - 169 | 17.25 | 17.655-18.73 | ||

Hydra HM Bridge Plug is hydraulically actuated and mechanically set,thereby eliminating the need for an external mechanical or wireline setting tool. These Bridge Plugs can be run and set in tandem with retrievable production packers or squeeze packers. The plugs offer customer flexibility on deployment for zonal isolation, squeeze cementing, fracturing, and Plug & Abandonment.

Hydra HM Bridge Plug internal setting mechanism consists of Ball Seat, Setting Sleeve and Shear Stud. To set the Bridge Plug, a setting ball is dropped from surface and pressure is applied which sets the upper slips. Then the work string is picked up in tension which sets the packing element. The work string is then released by either shearing the shear stud or rotating 10 turns to the right.

| HydraHMTM Hydro-Mechanical Bridge Plug | |||||||

|---|---|---|---|---|---|---|---|

| Casing | Setting Range (Inch) |

Plug OD max. (inch) |

Shear Force (lbs) |

Thread Box Up |

Differential Pressure (psi) |

Elastomer | |

| OD (Inch) |

Weight (PPF) |

||||||

| 3 1/2 | 5.7-10.2 | 2.867-3.258 | 2.75 | 9,000-12,000 | 2-3/8” EUE |

10,000 | Nitrile / HNBR / Aflas / Viton |

| 4 | 5.6-14 | 3.34-3.732 | 3.12 | 20,000-25,000 | |||

| 4 1/2 | 9.5 - 16.6 | 3.826-4.09 | 3.5 | 22,000-30,000 | |||

| 5 | 11.5 - 18 | 3.92-4.56 | 3.71 | 22,000-30,000 | |||

| 5 1/2 | 13 - 25 | 4.58-5.047 | 4.24 | 22,000-30,000 | |||

| 5 3/4 | 22.5 - 25.2 | 4.58-5.047 | 4.24 | 22,000-30,000 | |||

| 6 | 14 - 26 | 5.14-5.595 | 4.75 | 22,000-30,000 | 2-3/8” EUE |

||

| 6 5/8 | 34 | 5.14-5.595 | 4.75 | 22,000-30,000 | |||

| 6 | 10.5 - 12 | 5.595-6.366 | 5.34 | 30,000-45,000 | |||

| 6 5/8 | 17 - 34 | 5.595-6.366 | 5.34 | 30,000-45,000 | |||

| 7 | 23 - 40 | 5.595-6.366 | 5.34 | 30,000-45,000 | |||

| 6 5/8 | 17 - 22 | 5.989-6.655 | 5.61 | 30,000-45,000 | |||

| 7 | 17 - 35 | 5.989-6.655 | 5.61 | 30,000-45,000 | |||

| 7 5/8 | 20 - 39 | 6.625-7.263 | 6.09 | 30,000-45,000 | |||

| 8 5/8 | 24 - 49 | 7.511-8.248 | 6.96 | 35,000-48,000 | 8000 | ||

| 9 5/8 | 29.3 - 53.5 | 8.435-9.063 | 7.71 | 35,000-48,000 | |||

| 10 3/4 | 54 - 81 | 9.25-9.784 | 8.71 | 35,000-48,000 | 3000 | ||

| 10 3/4 | 32.7 - 51 | 9.85-11.15 | 9.5 | 35,000-48,000 | |||

| 11 3/4 | 38 - 60 | 9.85-11.15 | 9.5 | 35,000-48,000 | |||

| 13 3/8 | 77 - 102 | 11.633-12.464 | 11.56 | 35,000-48,000 | |||

| 13 3/8 | 48 - 72 | 12.347-12.715 | 12 | 35,000-48,000 | |||

| 16 | 65-109 | 14.688-15.250 | 14.25 | 40,000-48,000 | |||

| 18 5/8 | 76-96.5 | 17.25-17.655 | 17.25 | 40,000-48,000 | |||

| 20 | 133-169 | 17.25-17.655 | 17.25 | 40,000-48,000 | |||

The Hydra ER Extended Range Bridge Plugs are specially designed to run through restrictions and then set securely in larger diameters below. These restrictions such as seating nipples often force tubing to be pulled before well service can take place. The Extended Range Bridge Plug eliminates this in many cases. These Bridge Plugs will set securely in any hardness casing.

| Hydra ER Extended Range Bridge Plug | ||||

|---|---|---|---|---|

| Plug | Setting Range (Inch) |

Seetings Tool | Differential Pressure (psi) | Elastomer |

| OD (Inch) |

GO | |||

| 1.406 | 1.610-1.995 | 1 ½ Shorty | 10000 | Nitrile / HNBR / Aflas / Viton |

| 1.750 | 1.905-2.441 | 1 11/16 Multi-stage | ||

| 1.906 | 2.156-2.765 | 1 11/16 Multi-stage | ||

| 2.187 | 2.375-3.000 | 1 11/16 or 2 1/8 Multistage | ||

| 2.281 | 2.441-3.343 | 1 11/16 or 2 1/8 Multistage | ||

| 2.500 | 2.875-3.500 | 2 1/8 Multi-stage | ||

| 2.750 | 3.187-3.920 | 2 1/8 Multi-stage | ||

Hydra WR Bridge Plug is deployed on wireline and set via the Wireline Adapter Kit attached to the Pressure Setting Assembly. It can alternately be lowered on Tubing and set via the Hydraulic Setting Tool connected to the Wireline Adapter Kit.

SWR Retrieving Tool is run in hole and latched on the Hydra WR plug with 5 to 10k lbs set down weight. This enables the differential pressures across plug to equalize and a 10 to 15k lbs overall releases the HydraWR Bridge Plug from the casing wall for safe retrieval.

| Hydra WR Retrievable Bridge Plug | |||||

|---|---|---|---|---|---|

| Casing | Setting Range (In) |

Plug OD |

Differential Pressure (psi) |

Elastomer | |

| OD (In) |

Weight (PPF) |

||||

| 3 1/2 | 7.7-10.2 | 2.992-3.068 | 2.700 | 8000 | NITRILE / HNBR / AFLAS / VITON |

| 4 | 9.5-11.0 | 3.476-3.548 | |||

| 10.46 - 12.95 | 3.340-3.476 | 3.187 | |||

| 4 1/2 | 9.5 - 13.5 | 3.920-4.090 | 3.750 | ||

| 13.5 - 15.1 | 3.826-3.920 | 3.650 | |||

| 15.1 - 16.6 | 3.754-3.826 | 3.625 | |||

| 5 | 11.5 - 15.0 | 4.408-4.560 | 4.125 | ||

| 18.0 - 21.0 | 4.154-4.276 | 3.969 | |||

| 5 1/2 | 13.0 - 20.0 | 4.778-5.156 | 4.625 | ||

| 20.0 - 23.0 | 4.670-4.778 | 4.500 | |||

| 23.0 - 26.0 | 4.548-4.670 | 4.406 | |||

| 7 | 17.0 - 26.0 | 6.276-6.538 | 5.969 | ||

| 26.0 - 32.0 | 6.094-6.276 | 5.875 | |||

Hydra MR Mechanical Bridge Plug is a field proven high pressure packer type plug, used for treating and testing multiple, selected zones. This tool has a large internal by-pass to prevent swabbing when running and retrieving. The by-pass closes during the set-ting of the plug and opens prior to releasing the upper slips to equalize pressure when unsetting . This tool also features an upper-slip releasing system that reduces the force required to release the packer. A non-directional slip is released first, making it easier to release the other slips.

| Hydra MRMechanical Bridge Plug | |||||

|---|---|---|---|---|---|

| Casing | Setting Range (In) |

Plug OD |

Differential Pressure (psi) |

Elastomer | |

| OD (In) |

Weight (PPF) |

||||

| 4 1/2 | 13.5 - 15.1 | 3.826-3.920 | 3.625 | 10,000 | NITRILE / HNBR / AFLAS / VITON |

| 9.5 - 13.5 | 3.920-4.090 | 3.750 | |||

| 5 | 18.0 - 20.8 | 4.156-4.276 | 4.000 | ||

| 11.5 - 15.0 | 4.408-4.560 | 4.125 | |||

| 5 1/2 | 20.0 - 26.0 | 4.548-4.778 | 4.406 | ||

| 14.0 - 23.0 | 4.670-5.012 | 4.625 | |||

| 7 | 26.0 - 32.0 | 6.094-6.276 | 5.875 | ||

| 23.0 - 29.0 | 6.184-6.366 | 5.969 | |||

| 17.0 - 26.0 | 6.276-6.538 | 6.000 | |||

| 9 5/8 | 40.0-53.5 | 8.535-8.835 | 8.218 | 5,000 | |