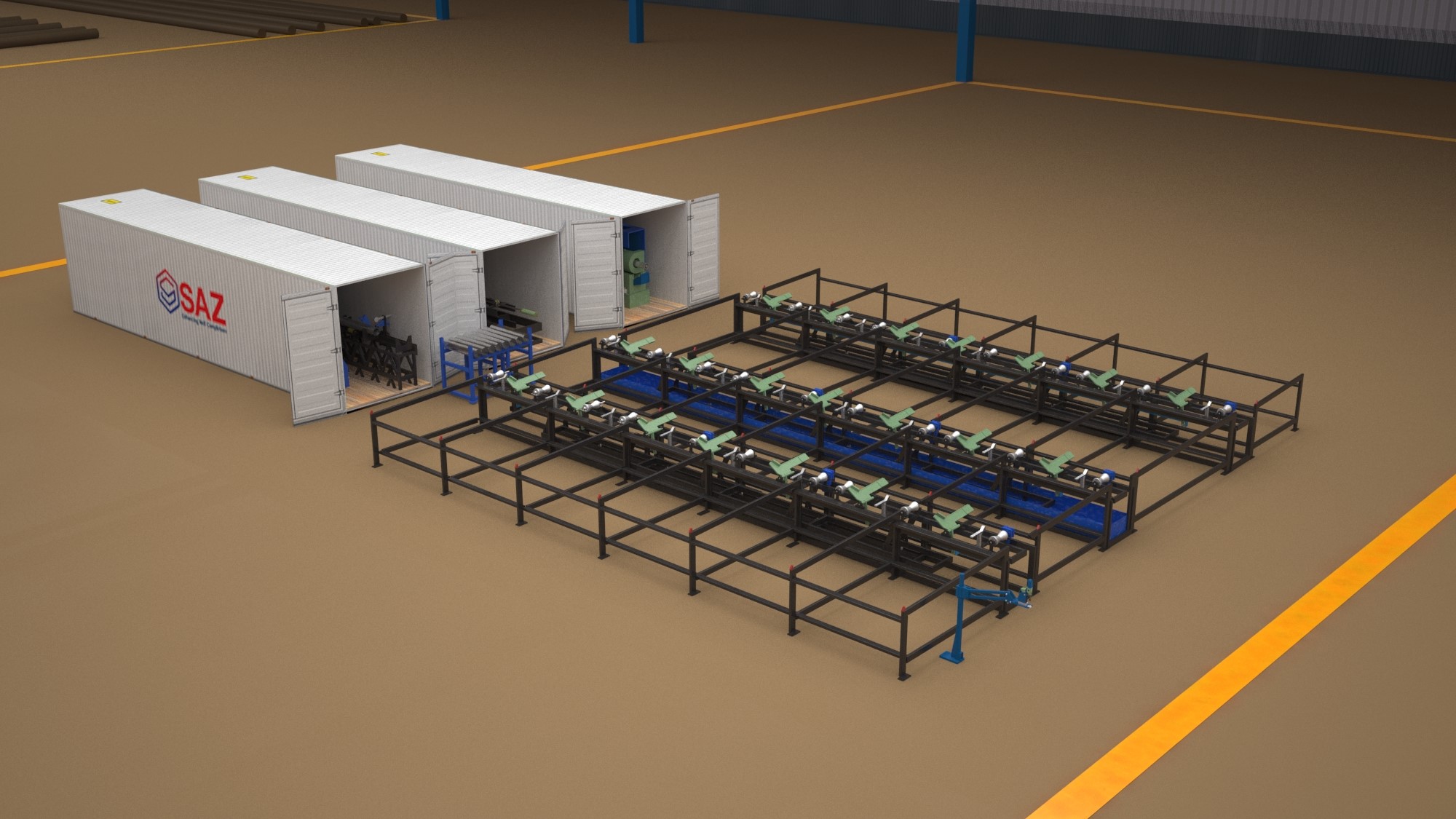

SAZ™ Modular Screen Plant

SAZ™ Screen’s manufacturing capabilities allows for flexibility on manufacturing location to support customer with their local content initiatives. Our Modular assembly plant can be quickly mobilized to enable local assembly of our proprietary pre-fabricated premium screens (SazPrime) and ICDs (FloPrime) on customer supplied base pipe, thereby reducing lead times and optimizing client inventory.

SAZ™’s unique, patent pending, manufacturing process enables us to take a fixed set-up factory type manufacturing process for sand control screens and flow control devices and convert it into a portable manufacturing facility that can be commissioned at the required site.

Modular Screen Plant: Enhancing Efficiency and Flexibility

The Modular Screen Plant exceeds the quality requirements of a traditional plant by rigorously following the ISO 9001 and API Q1 quality process. The screens are designed and qualified in accordance with API 19S.

A key enabler to this invention is the modular screen section. The 4ft ready to assemble screen modules, locally available base-pipe and SAZ™’s portable manufacturing set-up allows delivery of final product at end user’s doorstep in minimum possible time.

Advantages of portable manufacturing facility are:

- Smaller footprint compared to a traditional screen assembly plant;

- Shorter turnaround time for setting-up a factory

- Lower capital expenditure

- Allows local manufacturing in locations where it would otherwise be economically unviable to do so or where existing infrastructure is not suitable for large plants

- Reduces lead time by utilizing base pipe from local sources such as client’s existing inventory

- Improves inventory management for end users.

Modular Plant Features:

| Container based plant set-up

1. Basepipe drilling unit 2. Deburring/cleaning unit 3. Crimp and welding unit 4. Pipe decks (disassembled) 5. Drill and Tap unit |

Local set-up requirements

1. Workshop (covered) with level concrete floor 2. Mechanical lifting facility (forklifts) 3. Factory licenses (fire/municipal/labor/electricity) 4. Electricity and water supply. 5. Waste management – solids and liquids. |