SAZ Gravel Pack System

SAZ Gravel Pack System uses field-proven products and services to enhance well life by mitigating sanding challenges in unconsolidated reservoirs. The single-zone, cased hole gravel-packing system uses a simple and robust tool design.

Gravel Pack (GP), High Rate Water Packs (HRWP) and Frac-Packs (FP) are various methods to provide long term sand control in Cased Hole Completions. In gravel pack operations, a screen is placed in the wellbore and the surrounding annulus and perforation tunnels are packed with high permeability gravel/proppant properly sized to prevent the passage of formation sand into wellbore. It is critical to completely pack the space between the screen and formation to prevent the movement of formation sand into wellbore.

SAZ’s in-depth domain expertise, combined with our large portfolio of sand screens and sand control tools enable us to deliver enhanced Sandface completions.

Our Gravel Pack System combines Model BGCT Gravel Pack Crossover Tool and Model BH1 Hydraulic Setting Tool to perform reliable GP, HRWP and FP in Cased Hole. The same tool is used to deploy Stand Alone Screens in Open Hole with ability to washdown and displace the filter cake.

Features

- Packer setting and tool release achieved through pressure and vertical movement

- Contingency rotational feature to release tool from the Gravel Pack Packer

- High Tail Load capacity to deploy liners and screens in long horizontal wells

- Positive position indicating mechanism

- Setting tool is rotationally locked to the packer to allow torque transmission for deployment of assemblies in tortuous well paths

Applications

- Cased hole Gravel Pack and High Rate Water Packs

- Open hole stand alone screens applications with filtercake treatment

- Deep, deviated and horizontal wells

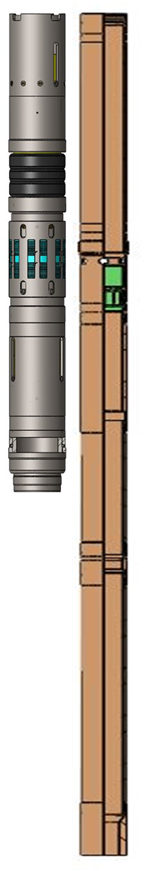

GPrime SR Retrievable Seal Bore Packer

GPrime SR Retrievable Seal Bore Packers are fully retrievable, high performance gravel pack and production packers. The packer is fully compatible with sealing system that consists of Seal Units, Self-Aligning Guide Shoe, Snap Latch or Anchor Latch Locator. The packer is tested and qualified in accordance with ISO V-3 and rated to 7,500-psi Differential Pressure at 250 degF. High pressure and temperature system available on request.

GPrime SR packer is set with GPrime Gravel Pack Service Tool and retrieved with GPrime Retrieving Tool using simple straight pull.

Features

- Short overall length facilitates easy running and retrieving through “dog-legs”, tight spots, and short radius curves

- Single, self-energizing “cup forming” packing element for repeated low and high differential pressure reversals

- Packing element is totally enclosed by chemically resistant, zero extrusion backup system to ensure extended downhole life

- High Flow Annular By-pass for displacement of fluid behind packer

- Cast iron construction of the exterior components allow emergency milling of the packer should it be impossible to retrieve by the conventional method (i.e. a straight pull)

- A hydraulically operated interlocking device, incorporated into the setting sleeve prevents the pre-setting of the packer during running in.

GPrime Gravel Pack Extension

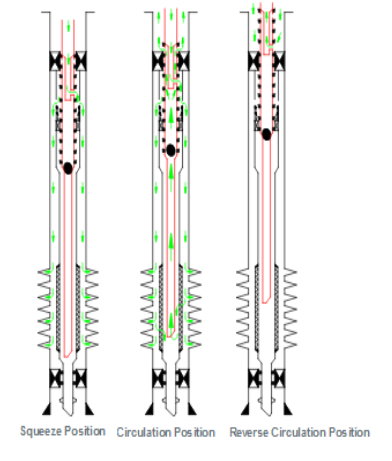

GPrime Gravel Pack Extension incorporates gravel-packing-ports sub with a closing sliding sleeve above a seal bore sub. The lower extension allows spacing the position indicating-cum-shifting tool to ensure proper shifting to various positions during gravel pack operations.

When the GPrime Gravel Pack Service Tool is pulled after completion of the gravel pack, the Shifting collet closes the Sliding Sleeve as it is pulled through. Capable to pump slurry of 10 ppg up to 20 bbls/min. and capable of handling 50,000 lbs of high strength proppant.

| GPrime SR Retrievable Seal Bore Packer | |||

| Casing Size (in) |

Weight (ppf) |

Seal Bore (in) |

Packer OD (in) |

| 9-5/8” | 47-53.5 | 6 | 8.33 |

| 7” | 26-29 32-35 |

4 | 5.99 5.82 |

| 5-1/2” | 13-20 | 3 | 4.63 |

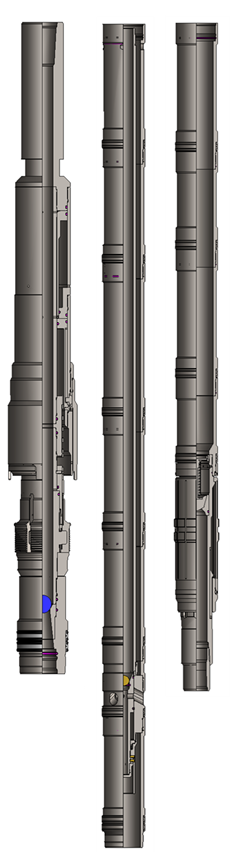

GPrime Gravel Pack Service Tool

GPrime Gravel Pack Service Tool consists of three modules-

- Top module – setting-retrieving mechanism

- Multiport module – crossover-circulating mechanism

- Lower module – check valve-indicating mechanism

Top module – setting-retrieving mechanism

- Tubing pressure actuated setting tool used in gravel pack operations.

- Short and compact -Increases the efficiency of handling, shipping, and storing as well as operations on the rig.

- Simple construction using minimum number of working parts, making it economical to maintain and easier to redress.

- The one-piece torque transmitting lugs give additional strength and reliability.

- Straight-pull release can be accomplished after applying annulus pressure.

- The rotational lock disengages automatically with applied tubing pressure, allowing emergency right-hand release from the packer

Multiport module – crossover-circulating mechanism

- Provides a rugged crossover system to achieve high rate and/or high-volume proppant injection.

- Provides a hydrostatic reference to make service tool operations independent of reservoir pressure.

Lower module – check valve-indicating mechanism

- Features a positive tool position indicating system which allows confident movement of service tool at the surface.

- Optional floating system available for offshore applications.

- Indicating/Shifting collet is installed below the Crossover Ports module to shift GPrime Gravel Pack Extension’s Sliding Sleeve.

- Automatic engage and release of Sliding Sleeve.

- Angled engagement surface for optimized shifting force.

GPrime Retrieving Tool

GPrime Retrieving Tool is used to release and retrieve (in a single trip) all GPrime SR style packers, including large bore, alternate bore, rotationally locked and hydraulic set versions. The tool consists of an anchor latch at the upper end and a spring-loaded catch sleeve at the bottom.

The GPrime Retrieving Tool is run on a workstring or tubing. At packer setting depth tool is engaged with the packer by setting 3000-5000lbs weight. Packer is released by picking up with a pull of 11000- 22000lbs force.

Features

- Release and retrieval of GPrime SR style packer in a single

- Suitable for use with drill collars and jars to aid in packer release and retrieval

- Simple construction with minimum parts

- Provided with a secondary release mechanism