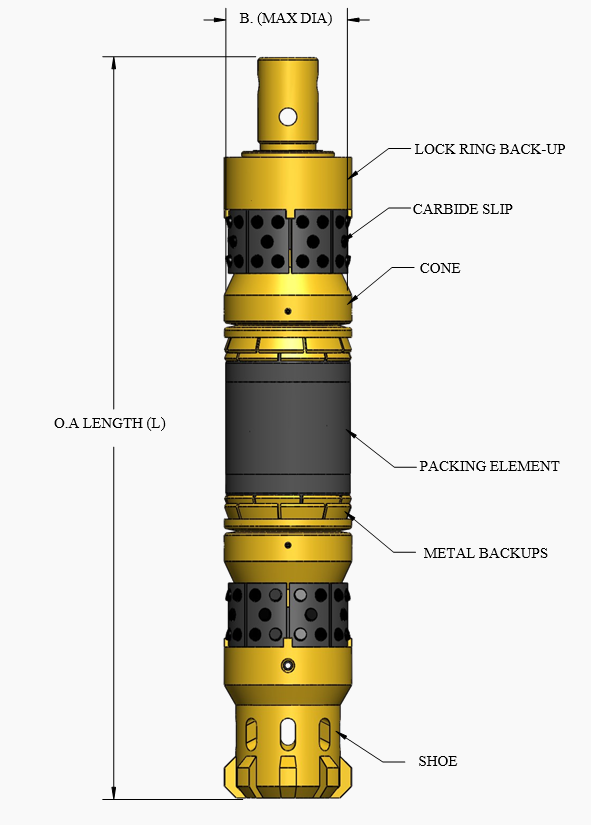

Hydra EX Aluminum Frac Plug

The Hydra EX Aluminum Frac Plugs are specially designed for zonal isolation in extreme conditions encountered during fracturing treatment in a Multi Stage Stimulation application. The Aluminum body with rotationally locked components provides ease of Milling and the slim OD enables rapid deployment via Pump Down Wireline in long laterals.

The bi-directional Tungsten Carbide Button Slips and a solid Aluminum core allows the Frac Plug to hold high pressure from both directions. The Hydra EX Frac plug features a one-way, internal check valve that is closed with a ball while the zone above the plug is fractured. The plug can be run with the ball in place or the ball can be dropped from surface when the plug is in position, or a caged-ball configuration also can be used. The check valve allows free flow of fluids from below the plug after the stimulation operation is completed thereby allowing frac flow back without having to mill the plug. Our Hydra EX Aluminum Bridge plug cum Frac plug can be quickly milled without any challenge or spoiling any well environment.

- Rated up to 15,000 psi [103 MPa].

- Rated up to 400°F [204°C].

Application

- Vertical, deviated, and horizontal wells.

- Zone isolation during multistage stimulation.

- High Pressure and Temperature.

Benefits

- Frac Plug withstands multiple pressure reversals to reduce rig time and costs.

- Easily deployed on Tubing or Wireline, with pump-down feature.

FEATURES

- Aluminum material which is Nondegradable.

- Unique activation system to maintain a superior seal even under multiple pressure and temperature cycles.

- Unique Carbide slip Design to keep Carbide Wickers from chipping or cracking in heavy casing and slipping in softer casing.

- BackUp System to support to keep the Element locked in place.

- Hydra EX Frac Plugs avoids spinning during operations.

- Hydra EX Frac Plug has a positive engagement clutch to prevent spinning of bottom sub on top of the next plug in multiple-plug drill out.

| S.N. | TECHNICAL SPECIFICATION | |

| 1 | NAME AND ADDRESS OF MANUFACTURER | CPS Oil and Gas Equipments Pvt Limited,Unit No.1, Survey No.244, Orchid IndustrialEstate, Chinchpada East. Maharashtra, India. Pin Code: 401208. |

| 2 | PRODUCT NO. | CPS159 |

| 3 | PRODUCT NAME | FRAC PLUG |

| 4 | PRODUCT TYPE | PERMANENT DRILLABLE |

| 5 | PRODUCT CHARACTERISTIC | ISOLATION FRAC PLUG |

| 6 | SERVICE CLASS | STANDARD SERVICE |

| 7 | METALLIC MATERIAL | ALUMINUM |

| 8 | NON-METALLIC MATERIAL | AFLAS 90-70-90 DURO |

| 9 | DRIFT DIAMETER (CSG) | 2.797″ |

| 10 | MAX OD (B) | 2.750″ |

| 11 | O.A LENGTH (L) | 15.935″ |

| 12 | RATED MAX TEMPERATURE | 400°F |

| 13 | TEMPERATURE CYCLE RANGE | 100°F – 400°F |

| 14 | RATED PERFORMANCE ENVELOPE (POE) | YES |

| 15 | FRAC PLUG DIFFERENTIAL PRESSURE RATING | 15000 PSI |

| 15 a | FRAC PLUG BODY BURST PRESSURE RATING | NOT APPLICABLE |

| 16 | TOP CONNECTION | NOT APPLICABLE |

| 17 | BOTTOM CONNECTION | NOT APPLICABLE |

| 18 | CASING SIZE | 3-1/2″ TBG |

| 18 a | CASING PPF RANGE | 9.3 – 10.3 PPF |

| 18 b | CASING ID RANGE(SETTING ID) | 2.922″ – 2.992″ |

| 18 c | TUBING SIZE | NOT APPLICABLE |

| 18 d | TUBING PPF RANGE | NOT APPLICABLE |

| 18 e | TUBING ID/MIN ID (A) | NOT APPLICABLE |

| 19 | CONVENYENCE METHOD | WIRELINE |

| 20 | MAX. CONVENEYANCE DIA THROUGH CSG/TBG | 2.78″ |

| 21 | MIN ID (A) | NOT APPLICABLE |

| 22 | SETTING METHOD | WIRELINE PRESSURE SETTING(CHARGE EXPLOSIVE) |

| 23 | RETRIEVING METHOD | DRILL/MILL THROUGH |

| 24 | REPOSITIONING METHOD | NOT APPLICABLE |

| 25 | QUALITY GRADE & VALIDATION GRADE | Q3 & V6 |

| 27 | OPERATIONAL MANUAL REFERENCE NO. | CPS/DES/OM-159 |

| 29 | APPLICABLE REF. STANDARD | API 11D1 3RD ED |

| 30 | SETTING FORCE | 12,600 LBS ± 10% LBS |

| 31 | RELEASE FORCE | NOT APPLICABLE |

| 32 | RUNNING IN HOLD SPEED | 3 FPS |