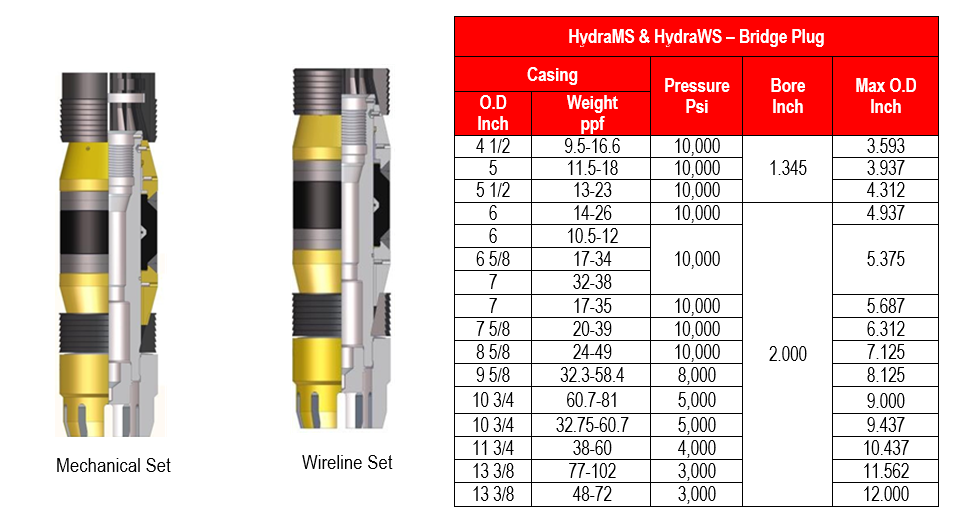

Hydra WSB and Hydra WSM Bridge Plugs

SAZ Oilfield Services offers a wide range of Bridge Plugs for permanent or temporary well bore isolation. Our HydraTM line of Bridge Plugs are based on field proven design and have an extensive track record globally over a wide range of downhole conditions.

Our Hydra WSB/ Hydra WSM Bridge Plugs are compact and economical unit engineered for fast running downhole on electric.

Application

- Multi-Zone isolation

- Multi-Zone stimulation

- Plug and Abandonment

Features and Benefits

- Available from 2-3/8” to 20” Casing Sizes

- Up to 10,000 psi & 400°F Rating

- Anti-preset mechanism

- Easy conversion to Cement Retainers

- Convertible from Mechanical to Wireline Set and vice versa

- Cast Iron construction, easily drillable

| Hydra WSM Bridge Plug | |||||

|---|---|---|---|---|---|

| Casing | Plug | Setting Range (In) |

Differential Pressure (psi) |

Elastomer | |

| OD (In) |

Weight (PPF) |

OD (In) |

|||

| 4 1/2 | 9.5 - 16.6 | 3.5 | 3.826-4.09 | 8000 | NITRILE / HNBR / AFLAS / VITON |

| 4 1/2 | 9.5 - 13.5 | 3.71 | 3.92-4.56 | ||

| 5 | 11.5 - 21 | 3.71 | 3.92-4.56 | ||

| 5 1/2 | 13 - 25 | 4.24 | 4.58-5.047 | ||

| 5 3/4 | 22.5 - 25.2 | 4.24 | 4.58-5.047 | ||

| 6 5/8 | 17 - 22 | 5.61 | 5.989-6.655 | ||

| 7 | 17 - 35 | 5.61 | 5.989-6.655 | ||

HydraWSM Wireline Set Bridge Plugs are available from 4-1/2” to 7” casing sizes. These Bridge Plugs are constructed with single piece elastomeric packing elements thereby providing an economical means for zone isolation, fracturing and other wellbore treatments. This plug sustains moderate pressures and temperatures.

HydraWSB Wireline Set Bridge Plugs are available from 2-3/8” to 20” sizes. These high performance Bridge Plugs contains three piece Elastomeric Elements with metallic back-up rings on either side of the Elements to avoid rubber extrusion in high pressure and high temperature environment. For larger plugs deployed in 9-5/8”, 10-3/4” and 13-3/8” casing sizes, the three piece packing elements are replaced with a single piece element, with option to retain the three piece element design.

| Hydra WSB Bridge Plug | |||||

|---|---|---|---|---|---|

| Casing | Plug | Setting Range (In) |

Differential Pressure (psi) |

Elastomer | |

| OD (In) |

Weight (PPF) |

OD (In) |

|||

| 2 3/8 | 3.3 - 5.9 | 1.71 | 1.867-2.107 | 10000 | NITRILE / HNBR / AFLAS / VITON |

| 2 7/8 | 6.4 - 6.5 | 2.1 | 2.28-2.563 | ||

| 3 1/2 | 5.7 - 10.2 | 2.75 2 | 2.867-3.258 | ||

| 3 1/2 | 12.7 | 2.5 | 2.625-2.75 | ||

| 4 | 5.6 - 14 | 3.12 | 3.34-3.732 | ||

| 4 1/2 | 9.5 - 16.6 | 3.5 | 3.826-4.09 | ||

| 4 1/2 | 9.5 - 13.5 | 3.71 | 3.92-4.56 | ||

| 5 | 11.5 - 21.5 | 3.71 | 3.92-4.56 | ||

| 5 1/2 | 13 - 25 | 4.24 | 4.58-5.047 | ||

| 5 3/4 | 22.5 - 25.2 | 4.24 | 4.58-5.047 | ||

| 6 | 14 - 26 | 4.75 | 5.14-5.595 | ||

| 6 5/8 | 34 | 4.75 | 5.14-5.595 | ||

| 6 | 10.5 - 12 | 5.34 | 5.595-6.366 | ||

| 6 5/8 | 17 - 34 | 5.34 | 5.595-6.366 | ||

| 7 | 23 - 40 | 5.34 | 5.595-6.366 | ||

| 6 5/8 | 17 - 22 | 5.61 | 5.989-6.655 | ||

| 7 | 17 - 35 | 5.61 | 5.989-6.655 | ||

| 7 5/8 | 20 - 39 | 6.09 | 6.625-7.263 | ||

| 8 5/8 | 24 - 49 | 6.96 | 7.511-8.248 | 8000 | |

| 9 5/8 | 29.3 - 53.5 | 7.71 | 8.435-9.063 | ||

| 10 3/4 | 54 - 81 | 8.71 | 9.25-9.784 | 5000 | |

| 10 3/4 | 32.7 - 51 | 9.5 | 9.85-11.15 | ||

| 11 3/4 | 38 - 60 | 9.5 | 9.85-11.15 | ||

| 13 3/8 | 77 - 102 | 11.56 | 11.633-12.464 | 3000 | |

| 13 3/8 | 48 - 72 | 12 | 12.347-12.715 | ||

| 16 | 65 - 109 | 14.25 | 14.688-15.25 | 2000 | |

| 18 5/8 | 76 - 96.5 | 17.25 | 17.655-18.73 | ||

| 20 | 133 - 169 | 17.25 | 17.655-18.73 | ||