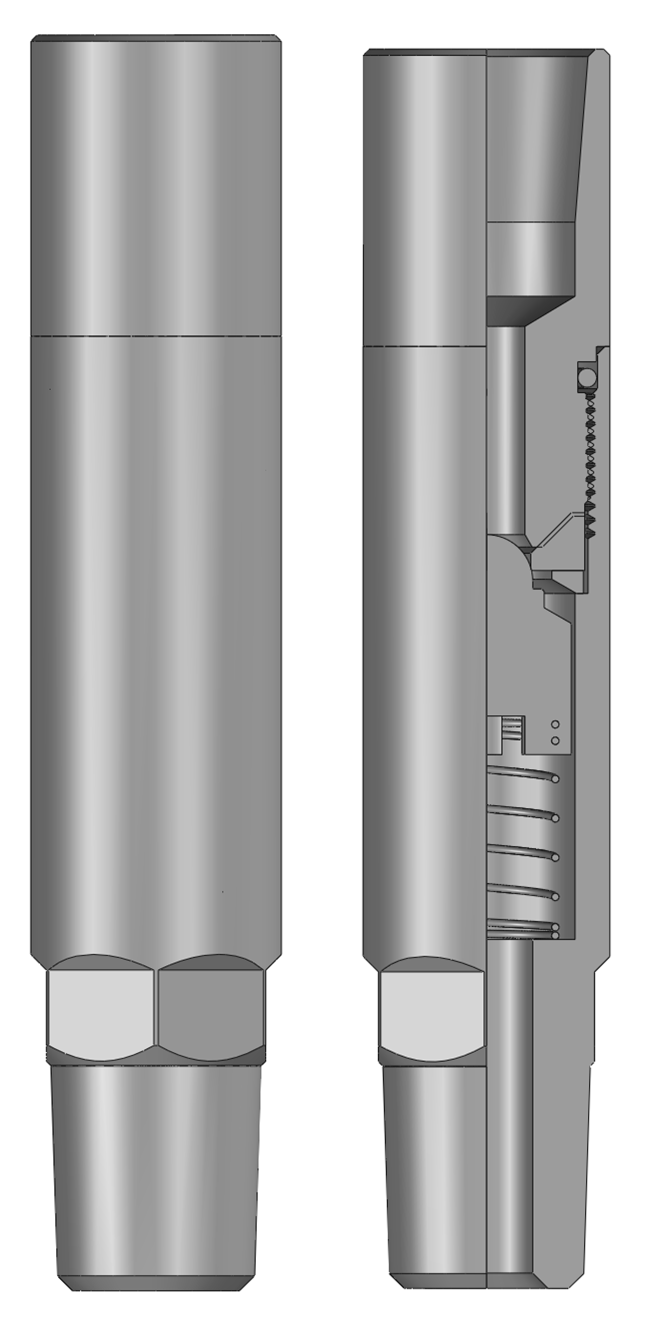

Orion CV Conventional Check Valve

Orion CV Conventional Check Valve are available in 1.0” and 1.5” diameter. The Check Valve is installed externally on conventional mandrel. Check dart prevents gas and fluid flow from the tubing back into the casing annulus. An elastomeric check pad is first contacted by the check dart and as differential pressure increases, a metal-to-metal contact acts as a secondary seal. The check valve is manufactured from premium material for corrosion resistance in wells with high concentrations of H2S and/or CO2.

Features

- Body material in stainless steel SS304/SS 316L, 17-4PH and Monel

- Check valve back pressure rating 5,000 PSI.

- Spring material Inconel X 750

- Compatible with other industry standard conventional (tubing retrievable) mandrels

| Orion CV Check Value | ||||

| Check Valve Type | Check Valve OD (in) | Effective Port Diameter (in) | Top & Bottom Connection | Flow Direction |

| Spring Loaded | 1.0 | 7/16 | 1/2″ NPT | Annulus to Tubing |

| 13/32 | 1/2″ NPT | |||

| 1.5 | 1/2 | 1/2″ NPT | ||

Please contact sales for custom sizes.