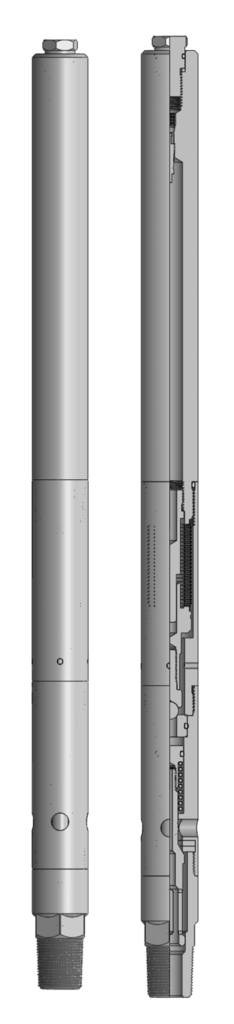

Orion PV Conventional Pilot Valve

Orion PV Conventional Pilot-Operated gas lift valves are available in 1.0” and 1.5” diameter. The valve is controlled by injection gas pressure (casing pressure). These valves are used to control lift gas during intermittent-gas lift operations. Intermittent gas lift re- quires instantaneous injection of large volume of gas for short period of time to lift the fluid from point of injection to the surface.

The Pilot valve consist of pilot section and power section. This valve utilizes pilot section to activate power section. The pilot section operates in the same manner as a single-element gas lift valve with a small choke located downstream of the valve seat. The injec- tion pressure at valve depth is exerted over the ball/seat contact area of the pilot section as an initial opening force. When the pilot section begins to open, an increase in pressure occurs between the pilot valve seat and the main valve piston. This increase in pressure above the piston results in compression of the spring under the piston, and the main valve snaps open.

Features

- Body material in stainless steel SS304/SS 316L, 17-4PH and Monel.

- Three-ply Monel bellows.

- Mechanical stop prevents bellows over stroke.

- Viscous fluid shear dampening prevents bellow fatigue and stem chattering.

- Tungsten Carbide ball and ball stem assembly.

- Replaceable floating Monel seat (also available in Tungsten Carbide material)

- Silver brazed bellows connections

| Orion PV Conventional Pilot Valve | |

| Size (in) | Thread Connection |

| 1.0 | 1/2”-14 NPT |

| 1.5 | 1/2”-14 NPT |

Please contact sales for custom sizes