Controller System

- Designed with the operator in mind

- Stand Alone or Modbus capable

- Low power and maintenance

- Plunger Lift SCADA Page coming soon!

- One model for all applications

- Timer

- Auto Adjust-Time

- Pressure Modes (transducers needed, sold separately)

- Load Factor–Open

- Pressure Open–TBG, CSG, Line

- CSG Upturn–After Flow

- Hi-Lo Controller

- Custom Applications available upon request

Arrival Sensor

- 3D Arrival Sensor

- Detects in 3 Axis, X, Y, and Z

- Class 1 Division 2 Certified

- Works with all major MFG controllers and SCADA

- 5 volt–28 volt systems

- Screw Cap with o-ring to deter moisture

- Test LED light in every unit

- Test switch to enable

- Sensitivity Adjustment in every unit

- Explosion Proof Container Available

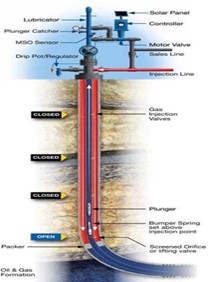

Gas Assisted Plunger Lift

- Gas Assisted Plunger Lift (GAPL) is a hybrid method of gas lift that utilizes a plunger to increase efficiency of lift gas

- Can help eliminate common GL inefficiencies

- Over Injection

- Liquid Slippage

- Paraffin Formation (cooling effect)

- Plunger provides a mechanical interface between gas & liquid

- Bypass plungers will not cause valve transfer issues and are appropriate tool for GAPL

- May delay or eliminate the need to pull TBG and redesign Gas Lift System as well conditions change

GAPL Benefits

- Interface provides full sweep of liquids in production string, where slippage typically still occurs

- Maximizes fluid recovery (oil)

- Paraffin Solidifies in upper end of production string where velocities are highest.

- Cooling effect occurs from injection point around GL valves, interrupting operation and hindering production. Plunger alleviates issue.

- Solids control (Scale and Iron Sulfates). Keeping tubing clear.

- Lower BHFP, lower drawdown will yield net production gains/uplift

- As this happens, have the ability to lower injection rates or eliminate injection Release compression, etc.

GAPL Candidate Selection

- Wells that produce up to 350-500Bblsliquids per day, depending on tubing size (2 3/8” 350BblsMax & 2 7/8” 500BblsMax)

- GLR equivalent to 350-500Bbls/750Mcf/d-1MMcf/d Gross Gas

- Depends on fluid cut (50%+ Oil = lighter weight = larger pool of well candidates)

- Have seen success with lower GLR

- Line Pressure has to be considered

- GL Designs with GAPL as long-term vision, can be more effective. Set SN just above bottom valve or screened orifice. A packer-less application can allow you to inject around EOT and right-size compression through the life of the well.

- Stand-alone Bypass PL (no Gas Lift assistance) can operate with up to 400 Bls/1MMcf/d, depending on tubing size, line pressure in field