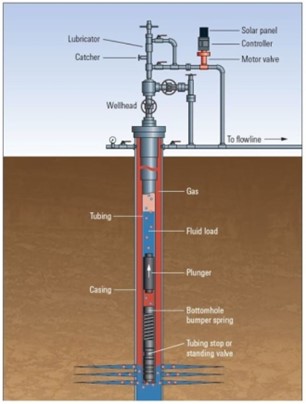

Plunger Lift System

SAZ Oilfield’s Plunger Lift System is an economical Artificial Lift method used to de-liquify gas wells and remove contaminants like sand, scale, paraffin and hydrates.

SAZ Plunger Lift enhances production by unloading liquid from the well with marginal flow characteristics due to liquid fall back. During high flow rates, the plunger stays at the top of the well and as soon as liquid loading occurs due to decline in production, the motor valve is closed and the plunger travels through the production tubing to the bottom of the well and lands on a bumper spring. With the well shut-in, the pressure builds up inside the annulus and the motor valve is opened lifting the plunger along with the fluids to the top of the well.

The plunger has enough clearance to allow it to move unhindered up and down the tubing string. However, the clearance is small enough to create a seal between the fluids above and below the plunger. The plunger movement inside the tubing scrapes any initial appearance of paraffin or scale deposits on the tubing string and lifts them to the surface.

An optimized plunger lift well is achieved when the well is operating at the maximum number of cycles possible with the energy available and at the lowest average flowing bottom hole pressure.

Benefits:

- Low initial investment (CAPEX)

- Low operating, repair and maintenance cost (OPEX and R&M)

- Rig not required for installation

- Cost of system is unaffected by well depth

Applications :

- For de-watering gas wells

- Enhance oil production in high Gas Liquid Ratio (GLR) oil wells

- To prevent paraffin and hydrate build-up

Well Candidates

Bypass Plunger

- Operating near critical rate and liquid loading

- Erratic/Unstable production

- Gassy Liquid Wells (particularly HZ/Directional/Shale)

- Paraffin deposits in the production string

- Wells that are currently in some form of intervention (swabbing/intermitting/soaping/venting)

Conventional Plunger

- Liquid Loading due to unstable rates

- High Tubing/Casing Differential (Liquid Loading indicator)

- Wells that are currently in some form of intervention (swabbing/intermitting/soaping/venting)

Plunger Types

Continuous flow / By-pass Plungers

These plungers are typically applied at or near critical velocity and require little to no shut-in, these type plungers open to allow gas passage on the downward travel and typically operate at gas velocities greater than 9 ft/s (calculated at the bottom of the tubing). These plungers are available in variety of types:-

- HSP Ball and Sleeves

- Dart Plungers

- Center Rod Plungers

Conventional Plungers

Conventional plungers are used in wells that require additional energy build-up in order to lift accumulated liquid and plunger. This build-up occurs while the well is shut in at the surface. Various types of Conventional Plungers are:-

- Bar Stock

- Padded Plungers

- Brush Plungers

Fast Fall Plungers

Fast Fall Plungers are designed to run 2-3 times as often as conventional plungers without using any external or mechanical shifting mechanisms. The reduction in close time allows for more cycles per day and optimal fluid removal. These plungers are available in two type:-

- Raptor Fast Fall

- Fast Fall Bar Stock

- TREX Fast Fall

Surface Equipment

Lubricators

- 8 Rd EUE Lubricators

- Bowen Lubricators

- Flange Bottom Lubricators

Downhole Tools

- Heavy Duty Bumper Springs

- Standard Bumper Springs

- Hold Downs and Collets

- Tubing and Collar Stops

- Multi-stage Tools

- Pack-off tools

- Standing Valves

Lubricator Catchers

- Manual Catcher

- Auto-Catcher

- Catcher Adaptors

Plunger Lift Electronics

- Controller

- Arrival Sensor

Anvil and Rod Product Lines

- Anvil Blind

- Anvil Bypass

- Anvil Rods

Accessories

- Plunger Picker Tool

- Plunger Magnets

By-Pass (Continuous Flow) Plungers

- By-pass or Continuous Flow Plungers are designed to fall through the flow of the well

- The “By-pass” area of the plunger allow it to fall against flow

- Utilize a valve seat mechanism to open and close by-pass area

- Can make several more cycles per day which yields more fluid removal per day (smaller liquid loads per cycle)

- Great for wells flowing at or near critical flow, wells that recover quickly and gas injection wells

- MUST BE ALLOWED to fall through the flow of the well, not recommended to run from bottom (excessive shut in time)

- Some can be used as “Quick Drop” Plungers but MUST make sure you have fluid to fall through and MUST make sure the plunger does not fall too fast.

By-pass Plungers–Cycle Frequency with By-pass Plungers

- By-pass Plunger cycles should be longer than conventional cycles (top-bottom-top of well)

- Pressure build-up is not necessary but rather flow of the well is important (flowing at or near Critical Flow Rate)

HSP Ball and Sleeve Plungers

- Utilize a two piece ball and seat type mechanism

- Ball weight and sleeve length matched with production volumes

- Able to fall against higher rates (rates of over 1 MCFD)

- Effective on very high rate wells

- Handle sand better than dart style plungers

- MUST be allowed to fall against flow, extremely fast fall speeds and high im- pacts (over 2500ft/min)

- Proper ball and sleeve pairing is vital

Features

- Choked sleeves to help reduce fall velocity and impact

- Various lengths (6”, 8”, 9”, 10”, 12”,18” (2 7/8)

- Medium to Heavy weight balls available for high flow are wells

- Available in 1-1/2”, 2-1/16”, 2-3/8”, 2-7/8”

Dart Plungers

Applications

- Free-flowing, Gas Lift, and Wells in early stages of Liquid Loading

- Moderate to High Rate Production Volumes (Up to 200 bbld)

- Light Paraffin and Solid Production

- Controlled fall speeds and reliable clutch in wet and gassy wells

Features

- Needs very little shut in time (less than 5 seconds) to fall

- Does not need Shut-in to fall (clutch keeps by-pass area open)

- Can fall against rates up to 1200 MCFD and over 200 bbld

- Angled Slots help promote rotation for even wear distribution

Padded Dart Plungers

Applications

- Free-flowing, Gas Lift, and Wells in early-mid stages of Liquid Loading

- High Line pressure wells

- Lower to Moderate Rate Production Volumes (Up to 80 bbld /600 MCFD)

- Recommend clean wells (little to no paraffin, salt, sand)

- Controlled fall speeds and reliable clutch in wet and gassy wells

Features

- Needs very little shut in time (less than 5 seconds) to fall

- Does not need Shut-in to fall

- Can fall against rates up to 800 MCFD and over 60 bbld

- Machined pads help create a seal to utilize lift gas

- Can be used as a quick drop

Center Rod Plungers

Applications

- Free-flowing, Gas Lift, and Wells in early-mid stages of Liquid Loading

- Lower to Moderate Rate Production Volumes (Up to 80 bbld / 800 MCFD)

- No separate rod required, best option on odd lubricators where conver- sion is not available

Features

- Needs very little shut in time (less than 5 seconds) to fall

- Does not need Sut-in to fall against flow

- Machined pads help create a seal to utilize lift gas

- Can be used as a quick drop

- Available in 2-3/8” (Padded Only) and 2-7/8”

- No by-pass area, solid body mandrel

- Wells flowing near and below critical flow

- Lift larger liquid loads per cycle bypass plungers (less cycles per day)

Conventional Plungers

Rotary Sand Plungers

Applications

- Economical Solid and Hollow Body Plunger

- Wells with solids, hydrates, and paraffin production

- Rifles promote aggressive rotation for even wear distribution

Features

- Available in various lengths for different applications

- 4140, 17-4 SS, Hardened Black Diamond Coating Available

- Solid or hollow body

- Available in 1-1/2” to 3-1/2” pipe sizes

Scale Buster Plungers

Features

- Solid Body design constructed from 4140 heat treated Steel

- Grooves facing up and down for effective paraffin and scale cutting

- Effective against salt, sand, and other solids when conventional plunger is needed

- Available for 2-3/8” and 2-7/8” Tubing Size

- Available in 12” and 18” length

Pad Plungers–Machined Pads

Applications

- 4140 Precision machined pads and body

- The design incorporates interlocking devices beneath the pad and along the top and bottom of the each pad to keep flow from passing under or around the pads

- Inconel pad springs are the most durable in the industry

- Wear indicators on each pad (top and bottom)

Features

- Available in single and dual pad designs

- Body OD of 890” to help utilize lift gas

- 4140 heat treated steel precision machined pads

- Available for 2-1/16, 2-3/8, 2-7/8” Tubing strings

Pad Plungers–Forged Pads

Applications

- Same applications as machined pad plungers

- Forged (cast) pads from 17-4 SS

- All SS version available (built to order)

- More economical than machined pads

Features

- Available in single and dual pad designs

- Body OD of 890” to help utilize lift gas

- 17-4 SS casted pads

- Available for 2-3/8” Tubing strings

Brush Plungers

Features

- Used as a cleanout plunger to help brush Tubing and clear solids

- Can be used in marginal wells

- Has the best seal compared to any plunger but with less life expectancy (usually 1-2 months max)

- High Temp Nylon Brush with 4140 HT body

- Available for 1-1/2–3-1/2” Tubing sizes

Decelerator Plungers

Features

- Used as a test plungers in wells that have bottom hole nipples

- 890” NO-GO bumper stop at the bottom of the plunger

- Can be used in marginal wells (regular inspections recommended)

- Pad body and Bar Stock body available

- Available forc2-3/8” and 2-7/8” tubing sizes

Fast Fall Plungers

Applications

- Used as a gap or bridge plunger between by-pass and conventional plunger cycles

- Falls significantly faster than conventional but not as fast as by-pass plunger

- NOT able to fall against flow of well (needs shut in time)

- Great for “Tight” gas wells or wells that recover quickly

Raptor Fast Fall Plungers

Applications

- Wells in the beginning stages of liquid loading

- Conventional plunger applications in wells that recover quickly

- High gas / high liquid / to low gas / low liquid wells

Features

- 3/8” bypass port to fall quickly to bottom

- First plunger of its kind to utilize a check valve that seals on the up-stroke

- Offset 5/16” extra strength coiled pin with 12,000lb shear strength to retain ball and seat

- No rod or conversion anvil needed in conventional plunger lift lubrica- tor

- Up to 725ft/min fall rate in gas and 100ft/min fall rate in fluid

Fast Fall Bar Stock Plungers

Applications

- Falls faster than a conventional bar-stock plunger

- NOT able to fall against flow of well (needs shut in time)

- Great for “Tight” gas wells or wells that recover quickly