SazPrime Premium Screens

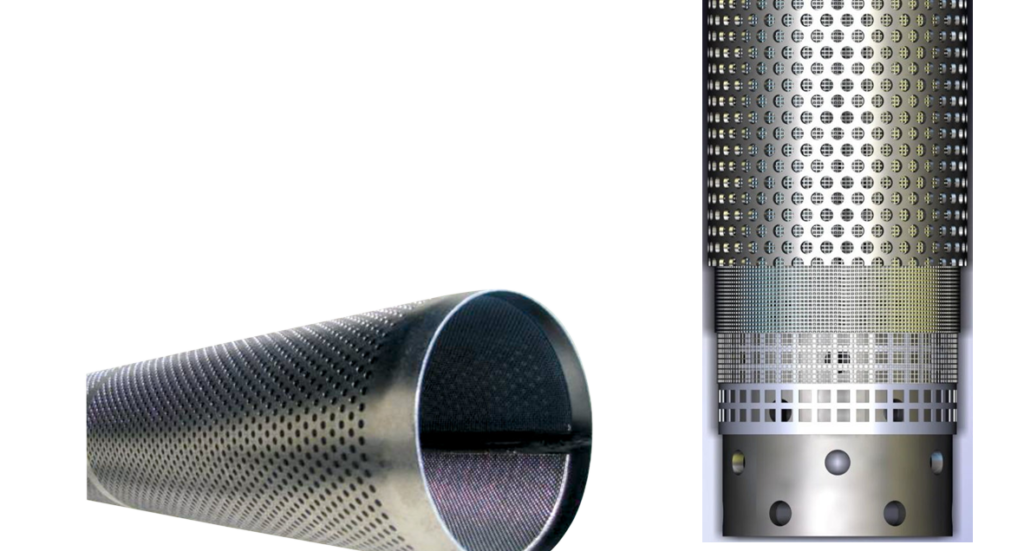

SazPrime Premium metal mesh sand control screens offer a unique screen design incorporating multiple diffusion bonded layers of woven metal mesh, creating a single monolithic sand control screen which is robust and has enhanced filtration specific characteristics.

Features

- Available in multiple configurations – combinations of number of filter layers, support layer and inner and outer shroud options.

- Available in various weave type – square, dutch, reverse dutch and SAZ exclusive Broadcast 3D weave.

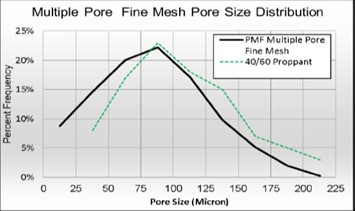

- Broadcast is a multiple pore sintered media that uses a combination of broad pore size range and high porosity to increase sand retention at all particle sizes with minimum plugging.

- Maximum initial and retained permeability compared to other screen options.

- Unique design eliminates all welds within the filter media resulting in a stronger overall structure and the elimination of any potential faulty welds.

- Precise woven metal mesh laminates achieve optimal filtration, uniform flow and mechanical strength.

- Diffusion bonded (sintered) designs result in a robust monolithic structure that provides fixed pore geometry.

- Fully annealed alloy provides superior corrosion protection.

- Available in standard SS alloys and Alloy 20.

Applications

- Openhole and Cased-hole completions.

- Vertical, deviated and horizontal completions for oil and gas wells.

- Inflow and Injection control wells.

- Thermal applications.

- Stand alone and gravel pack completions.

- Pump protection.

SazPrime HD

SazPrime HD is as high strength premium screen design for applications that need high burst and collapse pressure screens. The screen design incorporates a multi-layer construction wherein the filter layer is supported by a drainage layer below and a support layer outside. The number of sintered layers in the screen can vary between two to four layers depending on the application type. Multiple sintered layer provides the screen with high burst and collapse ratings.

Perforated shroud on the outside protects the screen media and provides a large surface flow area. The diffusion bonded layers with high performance mesh is designed for harsh environments.

Screen’s pore structure does not change under high deployment and operating stress loads. The screen pore structure stops heterogeneous sands, resists plugging, promotes high retained permeability, and resists erosion which are key factors for unconsolidated and heterogeneous long horizontal wells.

| SazPrime HD High Pressure Premium Screen | |||||

| Basepipe Nominal OD (in) | Nominal ID (in) (ppf) | Screen OD (in) | Perf size (in) | Perf Density (HPF) | Pipe Open Flow Area (%) |

| 3.5 | 2.992 (9.2) | 4.078 | 0.375 | 96 | 8.0% |

| 4 | 3.476 (11) | 4.578 | 0.5 | 72 | 9.4% |

| 4.5 | 4.000 (11.6) | 5.048 | 0.5 | 72 | 8.3% |

| 5 | 4.408 (15) | 5.578 | 0.5 | 84 | 8.8% |

| 5.5 | 4.892 (17) | 6.078 | 0.5 | 96 | 9.1% |

| 6.625 | 5.921 (24) | 7.228 | 0.5 | 108 | 8.5% |

Note: Screens available with API/Premium/Flush thread connections

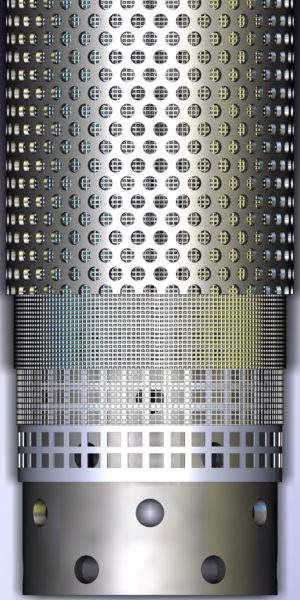

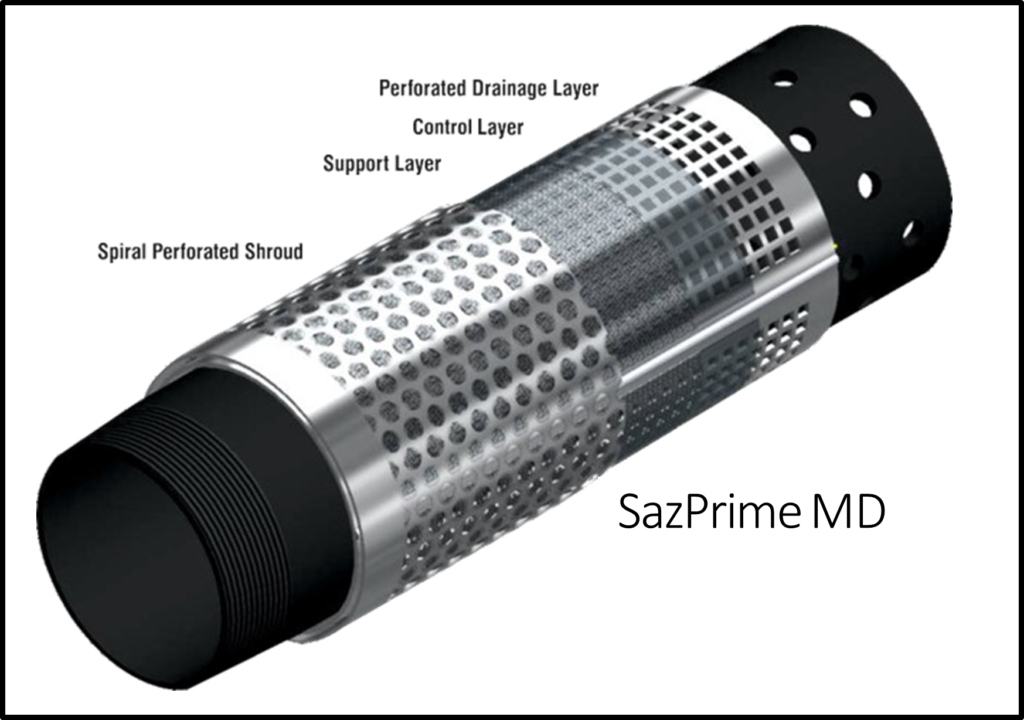

SazPrime MD

SazPrime MD is a modular screen design that offers a monolithic screen cartridge that can be assembled locally as part of our Modular Screen plant set-up. This screen is ideal for projects that require high local content by enabling local assembly of screens on customer supplied base pipe. This proprietary screen design includes a spiral shroud on the outside of filter layer and a perforated support plate beneath the control layer. The unique perforated drainage layer adds to the strength of the screen assembly. Perforated shroud on the outside protects the screen and provide for a large surface flow area. It is a high-performance screen design that offers high burst and collapse ratings.

The diffusion bonded layers with high performance mesh is designed for harsh environments. Screen’s pore structure does not change under high deployment and operating stress loads. The screen pore structure stops heterogeneous sands, resists plugging, promotes high retained permeability, and resists erosion which are key factors for unconsolidated and heterogeneous long horizontal wells.

| SazPrime MD Modular Premium Screen | |||||

| Basepipe Nominal OD (in) | Nominal ID (in) (ppf) | Screen OD (in) | Perf size (in) | Perf Density (HPF) | Pipe Open Flow Area (%) |

| 4 | 3.476 (11) | 4.58 | 0.5 | 72 | 9.4% |

| 4.5 | 4.000 (11.6) | 5.08 | 0.5 | 72 | 8.3% |

| 5 | 4.408 (15) | 5.58 | 0.5 | 84 | 8.8% |

| 5.5 | 4.892 (17) | 6.08 | 0.5 | 96 | 9.1% |

| 6.625 | 5.921 (24) | 7.23 | 0.5 | 108 | 8.5% |

Note: Screens available with API/Premium/Flush thread connections

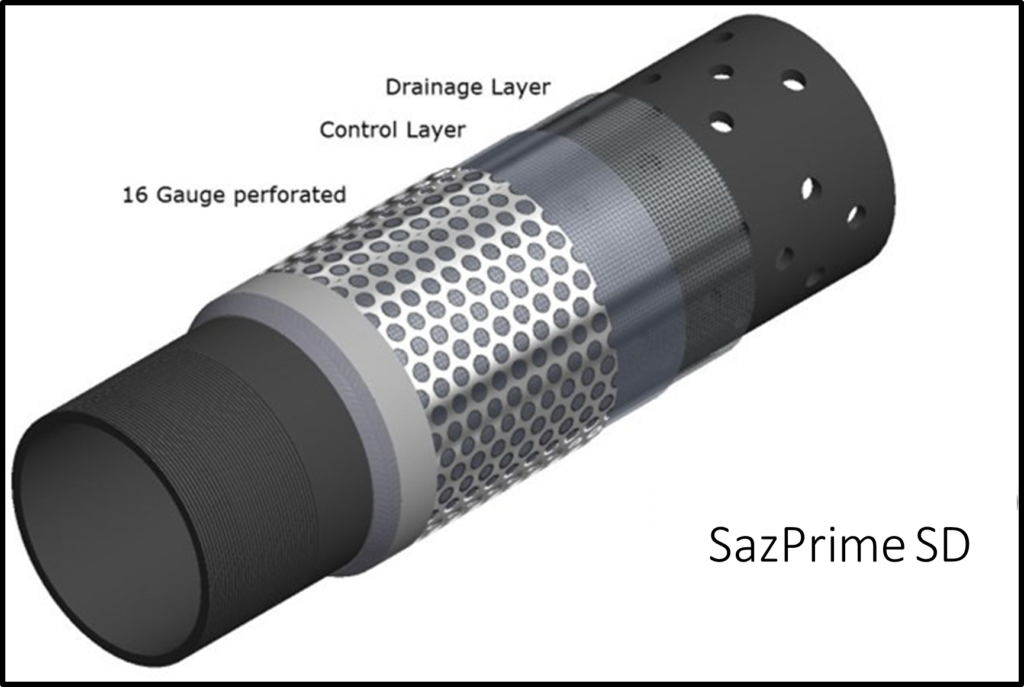

SazPrime SD

SazPrime SD is a standard premium screen design for applications where high collapse and burst pressure screens are not required. It’s unique construction method – filter / control layer supported by a drainage layer and a perforated shroud on the outside – are all sintered together as a sheet and then rolled into jackets. This fully integrated shroud with high performance mesh can be adoptive for various applications. Screen’s pore structure does not change under high deployment and operating stress loads typical of thermal heavy oil horizontal wells. The screen pore structure stops heterogeneous sands, resists plugging, promotes high retained permeability, and resists erosion which are key factors for unconsolidated and heterogeneous long horizontal wells.

| SazPrime SD Standard Premium Screen | |||||

| Basepipe Nominal OD (in) | Nominal ID (in) (ppf) | Screen OD (in) | Perf size (in) | Perf Density (HPF) | Pipe Open Flow Area (%) |

| 3.5 | 2.992 (9.2) | 3.86 | 0.375 | 96 | 8.0% |

| 4 | 3.476 (11) | 4.36 | 0.5 | 72 | 9.4% |

| 4.5 | 4.000 (11.6) | 4.86 | 0.5 | 72 | 8.3% |

| 5 | 4.408 (15) | 5.37 | 0.5 | 84 | 8.8% |

| 5.5 | 4.892 (17) | 5.87 | 0.5 | 96 | 9.1% |

| 6.625 | 5.921 (24) | 7.01 | 0.5 | 108 | 8.5% |

Note: Screens available with API/Premium/Flush thread connections

MaxPerm 3D Weave

SazPrime Premium metal mesh sand control screens can be constructed with our proprietary MaxPerm 3D filter media that allows for a much superior screen filtration performance. Instead of traditional fixed gap pore structure of filter media, the MaxPerm 3D weaves offer a complex pore structure characterized as Fine, Medium and Coarse weave where a single weave can effectively control sand with a large particle Size distribution

MaxPerm 3D media consists of elongated pores which capture sand on the surface while maintaining excellent flow through the pore. Sand bridges form rapidly, thereby providing the fine filter bed required for maximum long-term sand control but with minimal plugging.

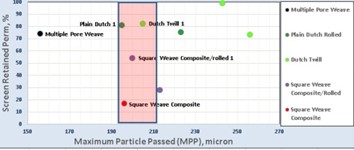

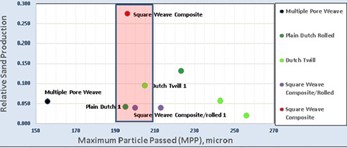

MaxPerm 3D weave performs remarkably better against other commercial weave types and same has been demonstrated under rigorous industry standard test method.

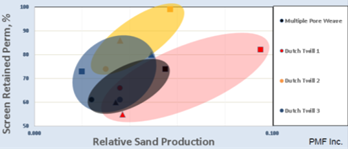

MaxPerm 3D allows minimal sand production while allowing very high retained sand permeability. For other weave types performance is significantly different within relatively similar pore sizes.

Test performance against different sand types shows a single MaxPerm 3D weave performance is more tightly bound as compared with other meshes. It is less sensitive to sand PSD because of the unique mesh structure, which provides a pore profile that more closely matches the range of all sand size distributions.