Surface Equipment

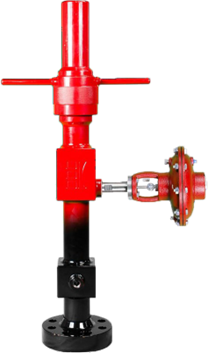

8 Rd EUE Lubricators Applications

- Low pressure application (3,000 psi & 5,000 psi)

- Sweet Gas and Low CO2 Applications

- Easy to install on the tree

Features

- 1026 Steel

- Extra heavy wall thickness

- 3K and 5K versions available

- Flange base and outlets Available

- Solid Cap with no Threads or Welds

- Screened Outlets to prevent ball down flow line

- Tested to 6000 & 7500 psi

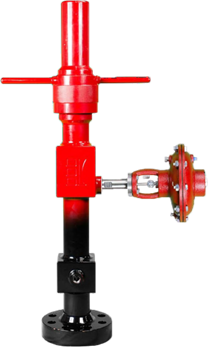

High Pressure Bowen Lubricators

Applications

- Higher Pressure Applications

- High Impact Velocity Applications

- Sour and Cold Service

Features

- Fully Machined Body

- Welded Versions are also available

- 4130 Q&T Steel

- All Caps have handles and ½” NPT port

- Meets or Exceeds API 6A, PLS 3 & NACE MR0175 Standards

- 5K and 10K flange options

- 5K version fail tested to 14,900 psi

| Lubricator Selection Guide | ||||

| Body Type | Welded Ports & Thread-o-lets | Welded Ports & Thread-o-lets | Fully Machined Body | Fully Machined Body *Welded Flange Ports* |

| MAWP | 3,000 psi | 5,000 psi | 5,000 psi | 10,000 psi |

| Tested Psi | 6,000 psi | 7,500 psi | 7,500 psi | 14,900 psi |

| Temp. Rating | (-) 20 to >180° F | (-) 20 to >180°F | (-) 50 to >180°F | (-) 50 to >180°F |

| Service Type | Sweet/Light H2S & CO2 | Sweet/Light H2S & CO2 | Cold and Sour Service | Cold and Sour Service |

| Cap and Threads | Fully Machined, 8 RD EUE | Fully Machined, 8 RD EUE | Bowen 4-3/4” ACME | Otis 5-3/4” ACME |

| Base type and Threads | 8 RD EUE Threads Flange, specified by order | 8 RD EUE Threads Flange, specified by order | Flange, Specified by order | Flange, Specified by order |

| Catcher Type | Manual/Auto/ Interchangeable | Manual/Auto Interchangeable | Manual/Auto interchangeable | Manual/Auto interchangeable |

| Manual Catcher | 5,000 psi | 5,000 psi | 5,000 psi | 10,000 psi |

| Auto Catcher | 5,000 psi | 5,000 psi | 5,000 psi | N/A |

| Material | 1026 Steel designed with extra wall thickness and 4 pass welds for longevity. Minimal Sour Service <0.05 psi Partial Pressure | 1026 Steel designed with extra wall thickness and 4 pass welds for longevity. Minimal Sour Service <0.05 psi Partial Pressure | 4140 & 4130w, 90,000- 120,000 tensile strength. No tubular welds on uni-body Meets or exceeds API 6A NACE compliant for sour applications | 4140 & 4130w, 90,000 -120,000 tensile strength. No tubular welds on uni-body Meets or ex- ceeds API 6A NACE compliant for sour ap- plications |

Auto Catcher

Applications

- By-pass Plungers running with After-flow

- Lower fluid volumes (helps prevent “Free-Cycles” and dry trips)

- Easy to install and maintain

- Interchangeable between 8Rd and Bowen Lubricators (Epic)

Features

- SS Material to prevent corrosion and rust

- Uses Kim Ray Top Works and stuff-n-box for high quality and

- Reliability S.A. products!

- Tested and Rated for up to 5,000 psi

- Adaptors available for most major MFG Plunger Lubricators

Anvil and Rod Product Line:

Anvil are used in the lubricator to stabilize the shock spring. The shock spring is fitted over the rod and the base section fits inside a groove at the top of the lubricator body. The lubricator cap is then fitted over top and screwed down.

Anvils

- Anvil for Most Major MFG plungers

- IPS

- PCS FB (RED AND BLUE LUBRICATORS)

- FLOW CO

- WELL MASTER

- WEATHERFORD

- DEFOPT

- PRIORITY

- 8 Lubricators and Bowen Lubricator Solid and By-pass Conversions Available

Rods

- Straight Rods at various lengths (24, 27, 35”) and thickness

- Tear Drop Rods for Ball and Sleeves

- Long and Short Rods

- Fat Boy Rods

- Tear Drop Groove