| Link to Single Entry | Incident No. | Incident Date | Item Part No. | Item Part Description | Quantity | Drawing No. | JO NO. | PO/SO. NO. | GRN/OR/CR No. | Operation | Created By | Created Date | Title | Incident Description | Standard | Reference | Type | Supplier / Customer Name | Upload Document | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| View Details | NCR-2024-00053 | 05/01/2024 | CBP1456M2 | Shoe 5610 | 0 | CBP1456M2 | J2212-0066 | Not Mentioned | Not Mentioned | Not Mentioned | QC | 05/01/2024 | Drawing dimension changed. NCR-24-001 | Design department did not change any dimensions on the drawing. | Not Mentioned | Not Mentioned | In-house | |||||

| View Details | NCR-2024-00046 | 01/02/2024 | CBG1035M1 | BODY FOR MAX OD 3500 (FOR GEO-DYNAMIC) MIDGET BRIDGE PLUG SUB-ASSY, MATERIAL : CLASS 40 GREY CAST IRON | 1 | CBG1035M1 | J2212-0026 | Not Mentioned | Not Mentioned | 4-CNC | QC | 01/02/2024 | NCR-23-69(Inprocess inspection) | Found blow hole during machining. | Not Mentioned | Not Mentioned | In-house |  | ||||

| View Details | NCR-2024-00047 | 01/03/2024 | CCW1243M | MANDREL, MATERIAL CLASS 40 GREY CAST IRON for 4312 WIRELINE SET SVCR | 1 | CCW1243M1 | J2311-0001.02 | Not Mentioned | Not Mentioned | 6--CNC TURNING - 5 | QC | 01/03/2024 | NCR-23-70(Inprocess inspection) | Thread cut on buttress thread approx | Not Mentioned | Not Mentioned | In-house |  | ||||

| View Details | NCR-2024-00048 | 01/03/2024 | CCW1243M1 | MANDREL, MATERIAL CLASS 40 GREY CAST IRON for 4312 WIRELINE SET SVCR | 1 | CCW1243M1 | J2311-0001.02 | Not Mentioned | Not Mentioned | 6--CNC TURNING - 5 | QC | 01/03/2024 | NCR-23-71(Inprocess inspection) | Blow hole on buttress thread approx. | Not Mentioned | Not Mentioned | In-house |  | ||||

| View Details | NCR-2024-00049 | 01/18/2024 | 147-005 | Round Bar Dia10 mm Material- Half hard Brass Hardness – 80 ± 5 HRB | 0 | 147-005 | Not Mentioned | PO2324/00377 | GR2324/00582 | Not Mentioned | QC | 01/18/2024 | NCR-23-72 (Incoming Inspection) | 1. No material grade mentioned in PO & TC. | Not Mentioned | Not Mentioned | Supplier | VIRAT STEEL & ALLOYS | NCR-23-72-Incoming-Inspection-PO2324000474_F11653.pdf | |||

| View Details | NCR-2024-00052 | 03/13/2024 | CI-CCW1035M4 | GUIDE, MATERIAL - CLASS 40 GREY CAST IRON | 75 | CI-CCW1035M4 | Not Mentioned | Not Mentioned | CR2324/00057 | Not Mentioned | QC | 03/13/2024 | NCR-23-75 (Incoming Inspection of Customer Material) | 1. Inspection report attached. | Not Mentioned | Not Mentioned | Supplier | SAZ Oilfield Services Private Limited | NCR-23-75-Incoming-Inspection-of-Customer-Material-CI-CCW1035M4_F13398.pdf | |||

| View Details | NCR-2024-00061 | 06/07/2024 | CGVW1NF713 | VEE PACK SEAL MATERIAL NEOPRENE+FABRIC 70DURO for 1" DUMMY WIRELINE GLV | 156 | CGVW1NF713 | Not Mentioned | Not Mentioned | Not Mentioned | Incoming Inspection | QC | 06/07/2024 | NCR-24-0017 | Outer diameter exceed maximum acceptable parameter. | Not Mentioned | Not Mentioned | In-house | |||||

| View Details | NCR-2024-00062 | 06/08/2024 | CCW1243M2 | GUIDE, MATERIAL CLASS 40 GREY CAST IRON for 4312 WIRELINE SET SVCR | 25 | CCW1243M2 | J2402-0034.05 | Not Mentioned | Not Mentioned | Final Inspection | QC | 06/08/2024 | NCR-24-0018 | Casting defect/blow hole found after final machining. 25numbers | Not Mentioned | Not Mentioned | In-house | |||||

| View Details | NCR-2024-00064 | 06/10/2024 | Not Mentioned | SEAL FOR 3 1/2" 9.3# L SLIDING SLEEVE MATERIAL : HNBR 90D | 8 | Not Mentioned | Not Mentioned | Not Mentioned | GR2425/00129 | Not Mentioned | QC | 06/10/2024 | NCR-24-0020 (Incoming Inspection ) | Inspection report attached. | Not Mentioned | Not Mentioned | Supplier | Name of Customer - Hindustan Oilseals Manufacturing Company | NCR-24-0020-Incoming-Inspection-.pdf | |||

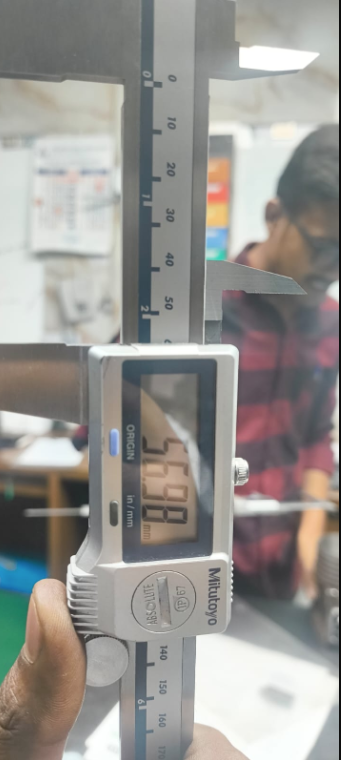

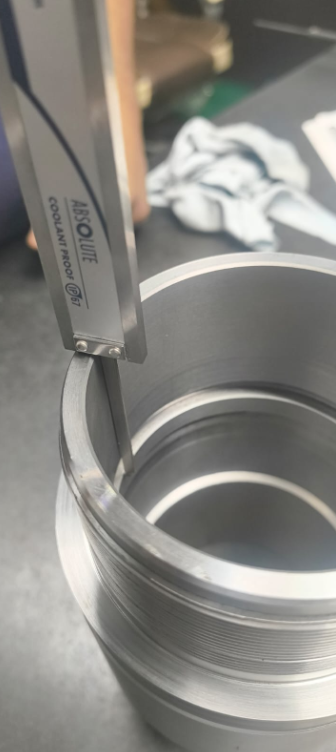

| View Details | NCR-2024-00065 | 06/19/2024 | CSNDX288F043 | PORTED SLEEVE FOR NON ELASTOMERIC, SLIDING SLEEVE DOWN TO OPEN MATERIAL : AISI 4140, 18-22 HRC OR EQ. TO L-80 | 0 | CSNDX288F043 | J2405-0083 | Not Mentioned | Not Mentioned | CNC TURNING PROCESS- 05 & 06 | QC | 06/19/2024 | NCR-24-0022 (Inprocess inspection) | 1] Thread pitch dia is more then required pitch dia.required pitch dia is 96.83496 to 97.00006 mm and observed pitch dia 97.25mm.also there is thread cut observed due t5o power cut. 2] Groove position is shift 5.15mm on upward direction. required groove distance from face is 61.97mm and observed 56.97mm.photo's is also attached. | Not Mentioned | Not Mentioned | In-house | |||||

| Link to Single Entry | Incident No. | Incident Date | Item Part No. | Item Part Description | Quantity | Drawing No. | JO NO. | PO/SO. NO. | GRN/OR/CR No. | Operation | Created By | Created Date | Title | Incident Description | Standard | Reference | Type | Supplier / Customer Name | Upload Document |